The Project

TECHNOLOGY

- Systems for the Side to Side (STS) mooring of the incoming LNG carriers and for LNG offloading

- Four LNG storage tanks with a total capacity of up to 153,500 cubic meters

- Three regasification units, each with a regasification capacity of 315.000 cubic meters (275 mmscfd) of natural gas/hour.

- Electricity generators for the power supply of the floating unit

- Metering unit for the measurement of the regasified volumes

- Crew accommodation facilities

288.6m

Length

44m

Βreadth

26.2m

Height

The floating unit is moored to its anchoring position through a permanent spread mooring 12 point system.

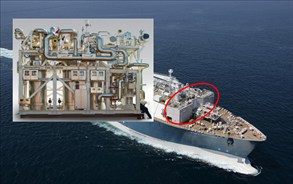

Regasification process

The liquified natural gas is offloaded from the LNG carriers and transfused to the cryogenic tanks of the floating unit. Next, it is gradually pumped to the three regasification units which are:

- Two closed loop technology units

- One open loop technology units

The regasification capacity of each unit is of 315.000 cubic meters (275 mmscfd) of natural gas/hour.

At the closed loop technology units, the LNG regasification is achieved through natural gas combustion, whilst at the open loop regasifiers, the LNG is heated using seawater supplied to the unit via suction pumps.

Following the regasification, natural gas is directed to the metering unit for measurement and onwards, through flexible pipes, to the Pipeline End Manifold (PLEM) where it enters the subsea pipeline for its transmission onshore.

Examples of LNG regasification units

open loop

closed loop

Subsea and onshore pipeline

The pipeline is designed with a diameter of 30 inches along its entire length and a maximum operating pressure of 110 barg.

Obviously, the operating pressure of the conductor depends on the corresponding operating pressure of the downstream systems to which it is connected.

The subsea pipeline of 24 km length will be placed in a trench and will be embanked along its entire length.

The pipeline crosses the shore at the Apalos area coastline and continues its route onshore northbound, burried in a trench, for 4 more km, until it reaches its connection with the NNGS (ESFA) at the new Metering / Regulating Station near the village of Amfitriti. The new M/R Station will be constructed and operated by DESFA (the NNGS TSO) to serve the needs of the Alexandroupolis INGS.

The Alexandroupolis INGS will have the ability to directly connect with other pipelines which are planned to be developed in the area in the future, such as TAP.

LOCATION OF THE PROJECTS

The Alexandroupolis & Thrace LNG terminals contribute to the diversification of natural gas sources and routes, to the promotion of competition in favor of the end customer, the security of supply of Greece and the Balkans, the optimization of the reliability and flexibility of the National Natural Gas Transmission System as well as of the Regional and Intereuropean Gas Systems, but also to the enhancement of the environmental targets of the country.

Οι σημαντικότερες ημερομηνίες για την κατασκευή του έργου

OPERATION

The LNG carriers transfer the liquid cargo to the FSRU tanks through cryogenic hoses.

The LNG is then gasified in the regasification facilities located on the floating unit and through a special installation the gas is transferred to the subsea natural gas pipeline, which after a route of 24 km crosses the shore of Apalos, east of Alexandroupolis. Then, continuing with a north course of 4 km, the gas arrives at the new Metering and Regulating Station in the area of Amfitriti where the INGS is connected to the National Natural Gas Transmission System.

The floating unit of Alexandroupolis INGS will be permanently moored at a fixed point and at a distance of 17.6 km SW from the port of Alexandroupolis and 10 km from the nearest coast of Makri.

The floating unit of Thrace INGS is planned to be anchored permanently at a distance of 8 km east of the LNG terminal “Alexandroupolis INGS”.